Switch to:

EN

EN  Português (PT)

Português (PT)  Español (ES)

Español (ES)

Surely you know someone who is afraid of boarding an aircraft equipped with turbo-propeller engines (and you yourself may share this fear). If the fear is even greater, flying in an aircraft equipped with piston engines may even be out of the question for some.

Despite the concerns of each passenger, fully understandable given the vastness of types of aircraft and models that fly today, the main pillar of executive aviation is flight safety. Despite common assumptions treating smaller aircraft as potentially unsafe or more fragile, what we see in practice is exactly the opposite: smaller aircraft are generally very robust and reliable for the most challenging operations.

Proof of this is that unpaved runways, small airports, and even remote locations in the interior of Brazil can only be reached by specific models — such as the Piper Seneca V, Cessna C208 Grand Caravan, or Pilatus PC-12, available for you here at Flapper.

Each aeronautical engine is built and designed according to the characteristics of each operation and, above all, of each aircraft. Shall we get to know the main types of engines and their characteristics?

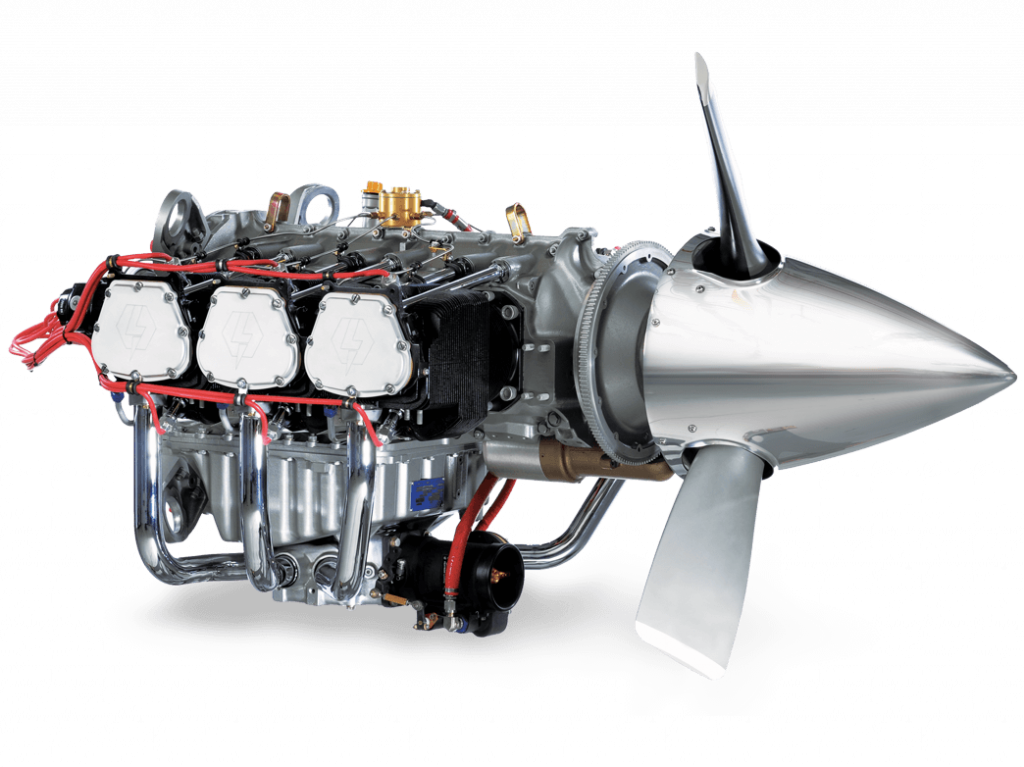

Piston engine

Among aeronautical engine types, this is the simplest model. One of the most reliable and robust, it has a simple operating structure, being similar to the operation of car engines. So much so that in some of the books used by pilots in their theoretical training, Volkswagen Beetle engines are compared to aircraft piston engines – given their similarity, ease of maintenance and repairability in a greater number of accredited workshops, and greater availability of skilled labor in the maintenance area.

The use of piston engines, in addition to providing versatility in operation, also leads to lower costs at the time of flight. This is because, in addition to maintenance being facilitated by the wide availability of qualified labor, these engines are powered by gasoline (AVGAS, 100 octane) instead of aviation kerosene (QAV, or JET-A1), with a lower cost per liter.

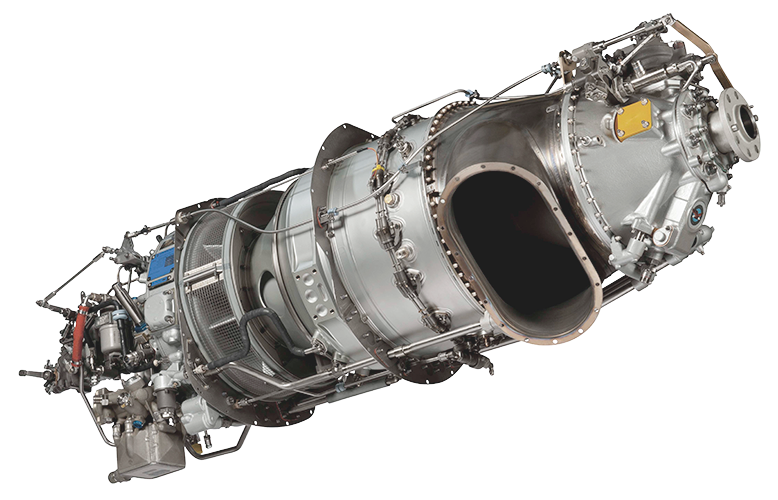

Turbo-propellers and Jet Engines

Although they don’t look like it, jet engines and turbo-prop engines can be placed in the same category: jet engines. This is because, although externally the similarities are very few, internally — in their systems and in their operating structures — these two types of engines have the same operating principle and, consequently, several similarities in their characteristics.

Turbo-propellers

Certainly the greatest difference between these two types of jet engine is the one that stands out the most to the eye: in turboprop engines, the large blades — sometimes higher than the aircraft itself! — are coupled to their own axis. This feature allows a great deal of traction to be generated, making the operation on short runways easier for both take-off and landing, when the greater traction results in a great effectiveness of the “reverse pitch”, when the blade angle is changed to mechanical braking aid, from the aircraft’s own brakes.

If we compare turboprop engines in terms of the greater torque produced, we can put it on the same level as a car with a turbo engine, where the maximum torque is reached at a much lower rpm compared to naturally aspirated engines.

Furthermore, in case of engine failure, the step adjustment is essential so that the so-called “flag step” is commanded. This must be done because, as the blades are quite large and represent a large drag area when not in operation, the aircraft must be aerodynamically clean, which facilitates the airplane’s controllability in extreme conditions.

One of the most established and reliable turboprop engine models on the market is the Pratt & Wittney PT-6.

Jet engine – or Turbofan

Jet engine – or Turbofan

The great advantage of turbofan engines is the conservation of their efficiency at high speeds, unlike turboprop engines. If we use the comparison with the car again, we would have two situations: a turbo car with excellent start in first gear with rotations, but with little efficiency at higher speeds and rotations (turbo-propeller) and a car with a naturally aspirated engine with less vigorous starts, but with great potential for developing strength and speed at higher rotations.

In addition, turbofan engines have as their main characteristic the great need for air flow, so that their operation is maximized. This is necessary so that the air ingested by the engine is admitted through the huge air inlet nozzles, compressed shortly after ingestion by the compressors, combusts in the combustion chamber, is accelerated in the turbine and, finally, expelled. All these phases, together, are responsible for giving power to the turbofan engine.

Generally, aircraft equipped with jet engines need greater airport infrastructure to operate safely, especially regarding the length of the runway for takeoff and landing. Another crucial factor in determining which aircraft is most suitable is fuel consumption: the hourly consumption of JET-A1 and/or aviation kerosene (QAV) can be, on some aircraft, twice as high compared to turboprop engines.

Knowing these basic differences between each type makes it even easier — and smoother! — to choose the right aircraft for each type of flight and travel even more smoothly. Flapper counts in its portfolio aircraft from operators accredited by the RBAC 135, which guarantees even more safety and reliability for operations in Brazil. As for foreign countries, all operators are approved by local aviation authorities, under strict quality criteria. All this so that you, our customer, can fly with complete safety and tranquility on any type of aircraft.

Take advantage of our empty-legs or, if you prefer, access our website or our apps (for iOS and Android) and book your tailor-made flight right now.